Chittaranjan Locomotive Works - Asia's Largest Electric Loco Hub

30-05-2016: My 4th

visit to Chittaranjan Locomotive Works. Early morning I board 12019 Howrah

Ranchi Shatabdi Express.

The train departs at 6:05am

sharp.

As we proceed, Howrah Loco Shed

passes by where I have been a regular for the last 7 years (My first visit was

in 2009). This is the shed

where Locomotive engineers have helped me quench my thirst about the

intricacies of Locomotives and shaped me up to whatever little I have known

about Locomotives till date. The shed whizzed past me in a flash.

Chai

time!!!

8:20AM

I reach Asansol at

8:20am.

I manage to go to the front of the rake and take a look at the

Locomotive that pulled my train. It was a HOG WAP 7 road numbered 30457.

Recently Howrah Shed has been allotted 5 Hotel Load WAP 7’s.

The HOG Locomotives are

being currently used in other trains and express’s for test purposes. It is

supposed to be finally implemented with hotel load power in Shatabdi and Rajdhani

Express.

I take a rickshaw to

Asansol bus stand from the station. From there I board a bus to Chittaranjan.

It takes me 45 minutes to reach Chittaranjan.

I visit the GM’s office

building where I was supposed to meet a friend of my Dad’s who is currently the

Dy CAO/TA at CLW.

But unfortunately, I couldn’t meet him. .

But unfortunately, I couldn’t meet him. .

I come across a poster in the GM’s office building where I find the “Make In India” campaign. This is our Prime Minister Narendra Modi’s project and is being currently implemented in many places including CLW.

I move to the D&D

building which is a few meters away from the GM’s office building.

Design and Development:

The

Engineer’s at Howrah Loco Shed where I have been a regular for more than 8

years have already informed the authorities at CLW, that I will be visiting the

factory for a day.

I meet the Dy Chief

Electrical Engineer, D&D and get involved in a conversation regarding the

status and the scenario of Locomotives

that are currently being rolled out from CLW.

The details shared by

him are as follows:

·

This year's Loco production target is 300.

·

Only WAP 7/WAG 9H/WAP 5 is being manufactured.

·

No more GTO based Loco's and hence Doppler Radar is not being

used in any G9 Loco. IGBT has solved the issue.

·

Hurth Coupling has been changed in few P5 Loco with another

alternative drive, just for experimental purpose. It is being supplied by

Henschel Germany.

·

CLW Dankuni to be operational by next year(only WAG 9

Locomotive will be made; 100 is the target).

1st Loco by CLW Dankuni: WAG 9 31713

2nd Loco by CLW Dankuni: WAG 9 31751

1st Loco by CLW Dankuni: WAG 9 31713

2nd Loco by CLW Dankuni: WAG 9 31751

·

For Hotel Load, target is 50 WAP 7 per year as of now.

Converter is being supplied by Siemens, ABB, Medha.

·

WAP 5 Hotel Load Loco to be out soon.

·

High Rise Pantographs are being installed in WAG 9H Loco.

·

Software is still MICAS. No up-gradation yet.

·

No more WAG 9 Loco is produced. It is WAG 9(H).

·

WAG 7 and WAP 4 production have stopped completely.

I meet AEE, D&D who happens to be a GP 140

Engineer. He shares some insights on Locomotives.

CLW has now started outsourcing many a component of the

Locomotive. It is necessary as CLW has to meet the demand of the increasing

number of Locomotives required every year by IR. The demand in the number of

Locomotives is because each year a lot of lines are getting electrified.

I am offered a cup of tea.

I then get my gate pass issued after my documents have been

verified by the authorities.

It is a special day permit.

I keep my bag in the D&D office. I am on my way to the

factory.

I enter the factory premises through the D&D gate.

Fabrication Shop:

I come

across the first workshop, i.e Fabrication Shop named ELF 17 and ELB 25

respectively. This time there are no shells of WAG 7 and WAP 4 as I had seen in

my previous 3 visits.

There were shells of WAG 9, WAP 7 and WAP 5. The Fabrication

shop has the longest bay amongst Locomotive factories in Asia. A new

Fabrication Unit has come up just beside the old shop, but it is half the size

of the original one.

The new fabrication unit has come up in order to meet the

demand of the increasing number of Locomotives.

There are bogies of WAG 9, WAP 7 and WAP 5 on the shop floor.

These bogies had been manufactured by private companies and are now being

assembled in the shop.

I spot the shell’s of the 3 Phase Loco’s which have been

manufactured by a private firm.

As I move further I find that the shells are being joined

with the side walls and the under-frame of the Locomotive.

There are approximately 20 Locomotives, being built and

assembled in the Fabrication shop.

Assembly Shop:

Then I proceed towards the Assembly Shop. I see a total of

about 30-40 Locomotives whose electronics, mechanical, pneumatic and electrical

components are being assembled. The components have been supplied by ABB,

Bombardier, BHEL, Medha, Crompton Greaves, Stesalit, Faively Transportation,

Autometers, Siemens and others.

There is no In house production of components like Auxiliary Converters,

Compressors, Transformers, Hotel Load Converters, Pneumatic Panel etc.

The Assembly shop is divided into 4 sections.

1. Wiring Section(Cabling of HB1, HB2, SB1 etc)

2. Transformer Section

3. Installing of Pipes and Pneumatic Equipments

4. Installation of Electrical equipment's such as converters,

auxiliary and control electronics etc

I meet few of the engineers who happened to be my Locomotive

teachers when I stayed at CLW in 2013 for a period of 3 weeks. They welcomed

me.

I had the privilege of discussing various issues with them.

One such topic was Hotel Load. Hotel Load is a new

application that has been introduced to eliminate the generator cars (EOG) used

in rajdhani and shatabdi trains. One of the major problems in Hotel Load (HOG) Locomotive is when the train passes through a neutral section.

When the Locomotive passes a neutral section power cannot be

generated at that particular point of time. Because of this, there will be no

power supply in the entire rake. The power is restored only when the Loco crosses

the neutral section. So, in order to avoid this measures are being taken. The

problem doesn’t occur if there is an EOG Car, since the power supply of the

coaches are delivered from the generator car.

Testing Shop:

I move to the Testing shop. 8 to 9 Loco’s are being tested.

There is no WAP 5 Locomotive, as they have been rolled out from the factory a

few day’s back. I see a Hotel Load WAP 7 and a WAG 9.

These two will be commissioned soon. The other Loco’s

are still in test mode.

The WAP 7 Hotel Load had a different type of braking system.

Basically two firms provides brakes. They are “Faively

Transportation System” and “Knorr Bremse”. The one I see is a Knorr type.

From there, I move to the paint shop.

Paint Shop:

I have never been

earlier to the paint shop as it is situated far away from other workshops.

There are 7-8 Locomotive’s ready to get painted. A few of them have already got

a fresh coat of paint and they need to be moved to the assembly shop.

Painting is also outsourced.

Painting is also outsourced.

I then proceed to the Motor shop.

Traction Motor Shop:

The stator and rotor are manufactured

here and the rest of the motor parts are supplied by private firms. I see more

than 100 squirrel cage induction motors ready to be put into service.

A little further away from the motor shop is another Motor

shop. Here I see DC Hitachi Motors. These will be supplied to WAP 4 and WAG 7

Locomotives as and when required.

These motors will be sent to the respective loco shed’s where

the conventional locomotives are housed. During POH (Periodic Overhauling) and AOH (Annual Overhauling), these will be replaced.

3.00 PM

It starts raining. It’s a smart downpour. I get inside the Assembly

shop. From there I ride pillion on an engineer’s bike to the D&D office. At

3.30 PM, I collect my bag and bid them goodbye. I thank them. They tell me to

come for a visit again.

I go to a nearby restaurant “Sonali” in Chittaranjan where I have some

food since I have skipped lunch.

At 4.30 PM I board a bus and reach Asansol at 6.00 PM.

12020 Ranchi Howrah Shatabdi arrives at 6.30 PM, 5 mins late

and departs at 6.31 PM from Asansol.

It arrives at Howrah at 9.30 PM, 25 mins late as there was a

derailment at Talit.

A day well spent.

A lot of things learnt.

2. Engineers

Brief History of CLW Technology:

LATEST UPDATES: (04-03-2018)

Shri V P Pathak, GM flagging off the First Loco with toilet facility in CLW on 1-6-17

Brief History of CLW Technology:

LATEST UPDATES: (04-03-2018)

Shri Rajen Gohain, Hon’ble Minister of State for Railways flagging off the 900th WAG-9H freight loco in CLW on 20-5-2017.

Shri V P Pathak, GM flagging off the First Loco with toilet facility in CLW on 1-6-17

GM CLW inaugurating the toilet facility in LOCO in CLW on 1-6-17

In an unprecedented performance, Chittaranjan Locomotive Works (CLW), a premier PUs of Indian Railways,has broken all previous records by producing 325 Elec loco much before the close of FY 2017-18. In a simple & sober send off the 325th Elec loco of this year 30667, WAP-7.

Factory: CLW Dankuni

WAP 5 FIRST HOTEL LOAD LOCOMOTIVE

Latest WAP 5 with aerodynamic cabs being manufactured at CLW.

Chittaranjan Locomotive Works (CLW) has turned out a new version of WAP-7 locomotive (WAP-7HS) capable of running at a speed of 160 kilometres per hour as against the present maximum service speed of 140 kilometer per hour of WAP-7. The locomotive shall be put into service after statuary tests and trials by Ghaziabad shed Northern Railways. The new type of locomotive is expected to facilitate the operation of premium trains such as Rajdhani, Shatabdi and, Duranto at a higher speed. The complete design and development of locomotive have been done indigenously at CLW. The necessary simulation and modelling are carried out by CLW in-house. To enhance the speed of the locomotive, a weight reduction of about 14 tonnes have been carried out. The gear ratio changed from 3.6 (72:20) to 3.2 (70:22). The software modification has been carried out to optimize slip-slide control and tractive effort.

Chittaranjan

Locomotive Works (CLW) produced its 7000th electric locomotive on 25th October.

Started in 1961, CLW moved from DC to AC and to then to IGBT based technology

locomotives. While first 1000 Electric Locos were produced in 25 years, the

last 1000 took just 2.5 years. Chittaranjan Locomotive Works (CLW) produced its

7000th electric locomotive on 25th October. Started in 1961, CLW moved from DC

to AC and to then to IGBT based technology locomotives. While first 1000

Electric Locos were produced in 25 years, the last 1000 took just 2.5 years.

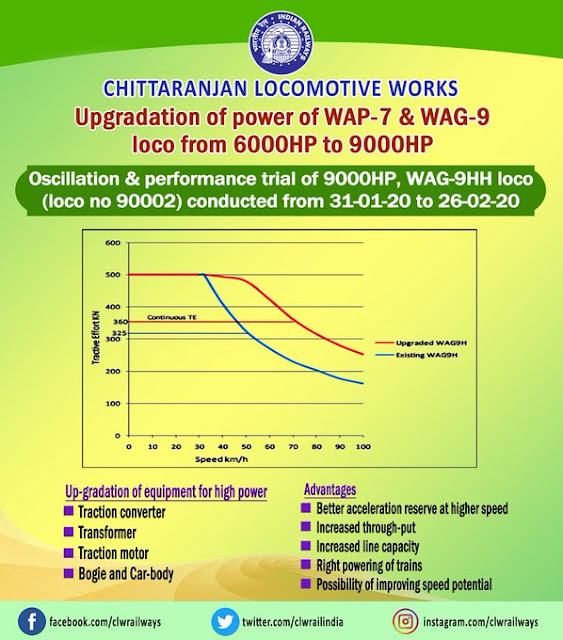

WAG 9HH (AS UPDATED ON 28-04-2020)

CLW built 9000HP WAG-9HH electric loco (Loco

no-90002) has successfully passed the oscillation and EBD trial by RDSO.

RDSO has issued final speed certificate

for operation of WAG-9HH class of loco.

A new prototype of WAP 5 Locomotive was developed in

CLW used for Tejas Express operation.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)